SPM Instrument - Condition monitoring technology you can trust

SPM Instrument is a global leader in condition monitoring technology. We have supplied the world’s industries with high-performance condition monitoring solutions for fifty years, and we are passionate about what we do. Our entire focus is on developing world-class products for world-class reliability and maintenance – that sets us apart from other suppliers.

Equipment for every application and monitoring need

As a full-range supplier, we exclusively develop and market all the technology to measure, analyze, and present condition data from complex machinery. The power of our innovations enables our customers to tap into the potential of the world’s most efficient condition monitoring solutions.

In addition to advanced measurement technologies, our extensive product line covers everything from transducers, transmitters, and cabling to power-packed online and portable instrumentation and software, as well as methods and products for corrective maintenance, such as laser shaft alignment and balancing.

Our leading-edge, intelligent condition monitoring solutions make an excellent foundation for a proactive maintenance strategy, integrated into normal maintenance activities, and effectively providing an overall picture of the status of critical assets. Immediate and evaluated condition information is presented as green-yellow-red condition codes for instant and easy recognition of trouble spots.

Unprecedented forewarning times with HD technology

We are the inventors of the ultra-efficient HD condition monitoring technologies. Providing unmatched forewarning times, they detect fault conditions well in time to plan maintenance and repairs for minimal interruption of the production process. Whether complex or straightforward, HD technologies have the power to address and resolve your reliability issues.

Qualified training at SPM Academy

Our training center SPM Academy offers standardized courses and customized training for all levels of staff involved in condition monitoring, enabling them to be fully proficient and continuously update their knowledge of our products and technologies. We are an accredited Mobius Institute Training Partner, offering ISO CAT I - III vibration analysis training with certification, as well as SPM certified Condition Monitoring Analyst courses.

Global presence

Our head office, including the R&D department, production facility, and training center SPM Academy, is located in Strängnäs, Sweden. The SPM Group is made up of more than two-hundred devoted professionals, eighty of whom are based in Sweden. Our highly trained global network of sales and service representatives – covering more than fifty countries – is here to support your maintenance department and help you get the most out of your condition monitoring program.

Contact us today – we look forward to hearing from you!

Our history

2023

Following the introduction to the Nordic market in 2021, SPM presents a global solution for the Airius® II LTE-M wireless vibration sensor in collaboration with network services provider Onomondo.

2022

SPM presents Airius II – an updated version of the Airius® suite of wireless vibration sensors.

SPM expands into process optimization as a new business area, utilizing HD Technologies for high-resolution data. The initial solution for optimizing tumbling mills expanded to vibration screens, catering to the mining industry. These advancements offer valuable insights into industrial processes, driving increased profitability and business growth.

2021

SPM introduces a four-channel version of the Intellinova® Parallel EN online system – a cost-efficient condition monitoring solution for compact machinery where a few measuring points are sufficient to cover all monitoring requirements.

Condmaster® Ruby with Decision Support System – a number of AI-based, data-driven software functions particularly useful for automating and streamlining the management of large online systems – is released.

Airius II LTE-M – the Airius® wireless vibration sensor for LTE-M communication is introduced.

2020

A new version of Condmaster® Ruby – our highly flexible diagnostic and analysis software, offering unique condition monitoring functionality and process optimization capabilities – is released. The new release arrives with optimal digitization and data exchange opportunities for IIoT environments as well as extended accessibility of condition monitoring data to more platforms to suit different user needs.

In addition to the battery-powered version, the wireless vibration sensor Airius® with external power is released.

SPM Academy introduces the course "Condmaster for advanced users", which focuses on deepening user knowledge of the Condmaster software and its components.

2019

SPM introduces the wireless vibration sensor Airius® and Condmaster.NET – an easy-to-use, web-based solution for the evaluation of measurement results from Airius.

The LineLazer app for easy machine alignment with the LineLazer sensors is released.

Updated versions of the popular portable instruments BearingChecker and VibChecker are released, with updated functionality.

2018

SPM launches a new version of the comprehensive condition monitoring diagnostics and troubleshooting software Condmaster® Ruby. The latest version is designed to deliver higher throughput, more connectivity options, advanced statistics functionality, and enhanced data reporting.

2017

SPM introduces Intellinova® Parallel EN – another milestone in the Intellinova® family of systems for continuous monitoring of rotating machinery. A new version of the comprehensive condition monitoring diagnostics and troubleshooting software Condmaster® Ruby was also released.

2016

SPM launches new wireless laser alignment sensors within the LineLazer concept for efficient and user-friendly shaft alignment.

2015

HD ENV® – a new pioneering method for vibration monitoring; DuoTech® – an accelerometer combining vibration and shock pulse measurement; Intellinova®Parallel MB – yet another version of our Intellinova system; and last but not least: a new version of the Condmaster® Ruby software were all introduced on the global market this summer.

At the beginning of 2015, we presented a new version of our popular Electronic Stethoscope and an Ex version of our Intellinova Compact online system – Intellinova Compact Ex.

2014

SPM releases the cutting-edge portable instruments Leonova Diamond®IS and Leonova Emerald®IS for extreme EX zones. IECEx and ATEX certified, providing sophisticated condition monitoring capabilities for potentially explosive industrial environments, including zones 0, 1, and 2.

2013

SPM launches Leonova Emerald®, a data collector in the Leonova line of portable instruments and sibling to Leonova Diamond®.

2012

SPM launches Leonova Diamond®, a portable instrument for condition measurement in rough industrial surroundings. Also, Condmaster®Ruby, a new version of the software used with our portable instruments and online systems, is released.

2010

SPM launches the revolutionary SPM®HD measuring technique. This digital refinement of the original Shock Pulse Method is applicable to all types of applications and is particularly well suited for low-speed machinery. Condmaster®Nova 2010 was also released, offering many new features. Among them is the Colored Spectrum Overview, a brand new way of presenting historical spectrums and viewing trends and patterns graphically.

2009

The portable instrument VibChecker hits markets worldwide. Like the popular BearingChecker, this new measuring device is an entry-level instrument for condition monitoring. VibChecker delivers reliable and accurate vibration information in just a few seconds.

2008

SPM introduces Intellinova® Standard, an online system for condition monitoring. The system uses well-proven methods and modern technology to ensure the highest possible accessibility on critical machinery.

2005

Leonova™ Infinity, BearingChecker, and the SLD transducer are released.

2004

LineLazer, the shaft alignment kit for Leonova™ is introduced.

2002

Another breakthrough in condition monitoring techniques: SPM Spectrum enables the first true and calibrated shock pulse spectrum analysis. Evaluated bearing condition measurement is combined with easy pattern recognition to verify the shock pulse source.

1997

EVAM is introduced, confirming the steady efforts of SPM to develop more straightforward and efficient evaluation methods.

1990

Shock pulse measurements and vibration measurements were combined in the first step towards comprehensive condition monitoring. At the same time, SPM developed life cycle analyses for an overall assessment of the economic consequences of condition monitoring.

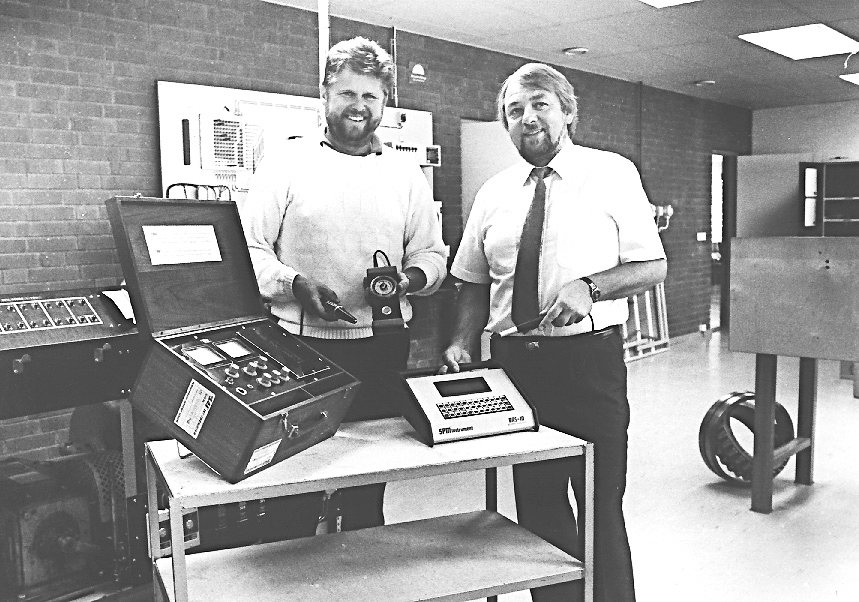

1984

After intensive work, we were able to incorporate, in the most profound sense of the word, the lubricating condition of the bearing into the SPM®Method. The second half of the 1980s saw a virtually revolutionary development of the software. Our world and that of our customers became computerized.

1980

SPM has installed millions of measurement points and has sold 40 000 units of the portable 43A measuring instrument – a true classic.

1970

The SPM company was formed. After only a couple of years, we developed the first rules for evaluating the measurement signals that Søhoel succeeded in isolating. Even today, we are devoting significant resources to developing these rules, both in the laboratory environment and on the industrial scene.

1969

Eivind Søhoel, the inventor, patented the shock pulse method that identifies the weak shock pulses from rolling element bearings.

1965

The history of SPM began in the 1960s. At that time, condition monitoring consisted of putting an ear to a wooden rod or screwdriver and listening to the sound of the machine. If something could be heard, it was usually already too late. A.P. Møller, the Danish shipowner, found out from bitter experience that the cargo pumps of his tankers were breaking down far too often without forewarning. An inventor and an enterprising financier decided to do something about it.